15 Nov What invention allows people to walk through walls?

This is not a riddle from the future, writes Abhishek Chhabra, Market Development Manager, Thomas Bell-Wright, but from the past… And the answer is doors. Doors are also the key element of compartmentation which, as discussed in his previous article, helps to enclose and entrap fire when and where it occurs.

So, apart from utilities which need to move in and out of the compartments created; we also need movement of living beings – using doors – and a need to access the outside which is fulfilled through windows. But unlike through penetrations, doors and windows need to open and close constantly. Hence designing, manufacturing, installing and maintaining a fire-resistant rated door or window requires more focus and attention as compared with walls and other passive fire protection solutions which are more static. Apart from this, there is a much higher degree of innovation in door designs because of their architectural value. So, very often doors and windows are the line leaders when industry wants to talk about compartmentation or passive fire protection.

To understand and ensure repeatability of performance of a fire door we need to focus on what are the processes that will bring about this repeatability. After all, if a ‘fire-door’ assembly has been put together and installed in a fire testing laboratory; there must be a way to do it exactly in the same way again. And the structured approach to assess what these processes are that lead to the creation of the exact same product which passed a fire test is called conformity assessment. Assessing the conformity of these processes that create repeatability are not just confined to where the doors and windows are manufactured or assembled but also extends to how they are installed at the project site as well as how they are maintained through-out their lifetime.

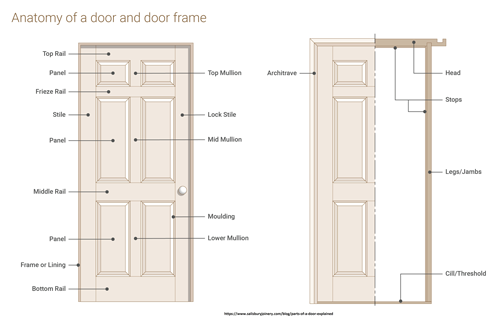

Image 1: Key parts of a door assembly

Compliance

There are basic building blocks of compliance but before delving deeper into how this would work for such products, we need to reflect on what is needed to ensure repeatability of:

A. Performance of materials and systems delivered to site

B. Workmanship for installation

C. Condition of the materials and systems after maintenance.

As the repeatable property in this context is fire resistance we must understand how this property is assessed. Coming as an evolved expectation from ‘compartmentation’ fire resistance rating is the property of a fire doors assembly to contain a (fully developed) fire within the compartment for a given duration. Some occupancy types need to maintain a compartmentation for just 30 minutes and others up to 1 or 2 or 3 hours! And the scenario of a fully developed fire is then created using a furnace which is capable of creating the temperature, pressure as well as the rate of increasing temperature (or change in pressure) according to how it can be in a real fire.

Across the world, different approaches have been documented in the form of test methods re-creating scenarios and detailing criteria to evaluate the ‘fire resistance rating’ of ‘fire doors”. A full review of how they are similar can be found online, but in summary:

EN 1634-1

The test determines the fire resistance of door and shutter assemblies and openable windows designed for installation within openings incorporated in vertical separating elements.

BS 476 – 22:1987: Section 6, 7 and 8 Corr 1:2014

Fire tests on building materials and structures – Method for determination of the fire resistance of non-loadbearing elements of construction when subjected to the heating and pressure conditions specified in BS 476‑20. It is applicable to vertical partitions, to fully insulated, partially insulated and uninsulated vertical doorsets and shutter assemblies (except fire dampers incorporated in ducts), to ceiling membranes, and to glazed elements.

ISO 3008-1:2019

This standard used in conjunction with ISO 834-1, specifies a method for determining the fire resistance of door and shutter assemblies designed primarily for installation within openings incorporated in vertical separating elements. Requirements are included for mechanical pre-conditioning, e.g. “cycling” of door and shutter assemblies prior to the conduct of the fire-resistance test.

UL10B:2008

These methods of fire tests are applicable to door assemblies of various materials and types of construction for use in wall openings to retard the passage of fire and are intended to evaluate the ability of a door assembly to remain in an opening during a predetermined test exposure. Any variation from the construction or conditions that are tested is capable of substantially changing the performance characteristics of the assembly.

UL10C:2016

These methods of fire tests are applicable to swinging door assemblies, including door frames with lights and panels, of various materials and types of construction for use in wall openings to retard the passage of fire. The method does not provide an evaluation of a swinging door assembly when that assembly is part of a larger assembly (e.g. sliding fire door assembly), or when it is intended to be used as an elevator entrance. Tests made in conformity with these test methods are intended to register performance during the test exposure and they provide a relative measure of fire performance of door assemblies under these specified fire exposure conditions.

UL10D:2017

These requirements cover the evaluation of fire-protective curtain assemblies intended to provide supplemental, passive fire protection as part of an engineered fire protection system. Fire-protective curtain assemblies are horizontally or vertically oriented which provide non-structural separation only, and are not intended to be substituted for structural hourly rated partitions or opening protectives that have been tested for fire endurance and hose stream performance. It does provide a relative measure of fire performance under specified fire exposure conditions.

NFPA 252

This standard prescribes standardised fire and hose stream test procedures that apply to fire door assemblies intended to be used to retard the spread of fire through door openings in fire-resistive walls. It allows different fire door assemblies to be compared with each other in order to evaluate their relative performance as measured against a standard fire exposure.

SANS 10177-2

This is the South African standard for fire testing of materials, components and elements used in buildings and covers the method of test used to determine the fire resistance of specific elements on the basis of the length of time within which a representative test specimen of specified dimensions will satisfy the criteria in respect of stability, integrity, and insulation.

IS 16947

The Indian standard for fire resistance tests for doors with glass panes, openable glass windows and sliding glass doors incorporated in vertical separating elements, such as hinged or pivoted doors, openable windows, sliding doors etc. The test provides for the determination of fire resistance of glass elements of architectural structures.

IS 3614

This Indian standard lays down quality requirements including the requirements regarding materials and details of construction of fire rated metal swing doors, wooden composite swing doors, metal sliding doors and metal rolling shutters. It also provides requirement on the supply, installation and maintenance of fire door assemblies. This standard does not cover doors which are horizontal or vertical sliding and swinging doors that are used in hoist way doors for lifts and dumb waiters. Fire safety curtains and vault doors are also not covered in this standard.

NFPA 288

This standard shall apply to horizontal fire door assemblies of various materials and types of construction that are installed in openings of fire resistance-rated floor systems or roofs to retard the passage of fire.

Initiations of assurance

When you link the section of ‘making a fire door’ and ‘compliance building blocks’ with how a typical procurement cycle of a fire doors gets initiated, you will realise why fire odours get the most attention.

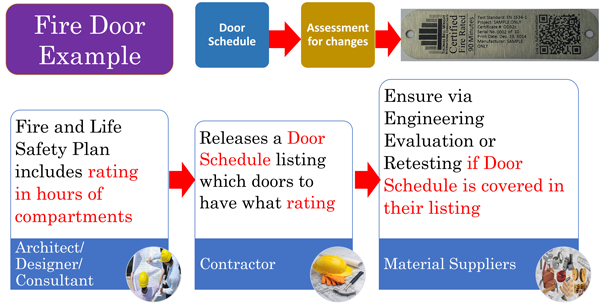

A fire and life safety plan is created as per the occupancy type and this defines where all compartmentation is needed and for how many hours. This is the starting point and a ‘door schedule’ is created identifying how many doors, where they are needed and their ratings. Before this is released as an enquiry to suppliers is when the real twist to the story begins. This is the intervention which defines how the door-assembly should look and function; creating variations of looks and hardware/ironmongery!

In countries where a rigid law on fire doors does not exist, some types of building get more attention than others. You can imagine between commercial and residential buildings which would get more importance. Higher accuracy is sought where the potential risk is higher: say a hospital, a school or a shopping mall should usually get more importance. This creates a need for more stringent method of assurance.

Focus areas of compliance

Moving from making of a fire door, it is understandable that assurance regarding the repeatable performance of fire doors, workmanship of installers of said doors and maintenance of same through the life of the building is unarguably essential. Compliance standards can cause confusion…

Typical procurement cycle of a fire door

Test report, certification and listing

The report of how a fire door performed when facing ‘standard conditions’ recreated in a laboratory to replicate a possible ‘fully developed fire’ in an occupancy type is called test-report. A well-established and correctly accredited laboratory will write in the traceability of the door sample in the test report. Where it came from and if the assembly of the door was witnessed by someone; along with other information related to conditioning, and in which supporting construction it was installed and by whom. This test report is sometimes called a test certificate and such a stand-alone document has little link with what will be manufactured and supplied by the same supplier listed as the sponsor of the test on the test report!

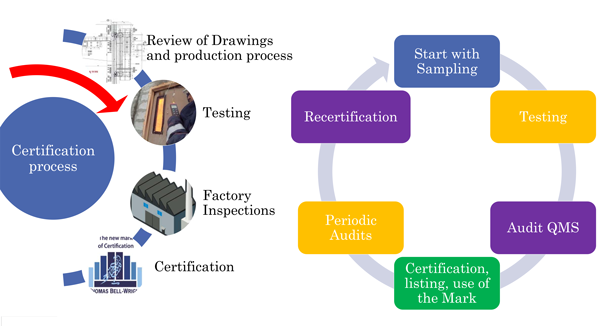

The general concept of certification and listing is described here but the exact methodology by which it can be conducted can vary between different certification bodies. Hence it is vital to know and probably even define the type of certification programme that could be acceptable considering the potential eventuality we are trying to avoid.

The ISO 17067(Fundamentals of product certification and guidelines for product certification schemes) guideline document defines how a Certification and Listing body needs to design and run their certification programmes.

The listing part of certification and listing should be detailed enough to assess the repeatability of the product at the construction site. These listing reports also provide traceability information using labels. These ideally list and limit hardware combinations and what is allowed.

The listing part of certification and listing should be detailed enough to assess the repeatability of the product at the construction site. These listing reports also provide traceability information using labels which ideally list and limit hardware combinations and what all is allowed to vary in comparison. Anyone close to the door assembly or fit-out contracting world love to jump-in and explain how it is impossible to cover everything and test everything every-time. And this is true to a certain extent. But then the need for assurance stems from the risk perception. And this is what defines what is the stringency level of assurance needed. The assurer is rarely empowered as policy, they either stand-by their reputation which is often backed by an accreditation audit or in some cases also has an additional responsivity they may have signed up with the governing authority (like a local or a regional fire department).

Typical procurement cycle of a fire door

Life and warranties of fire doors

After purchase and installation, like any similar product the owner has the greater share of the responsibility that the fire door will continue to work. The seller/ contractor may have some limited timelines till they stand behind the performance or none. This completely depends on the contract between the seller and the buyer. If there is nothing, then there is nothing. In some regions, the legal framework of the country or the region mandates certain performance guarantees or assurances of some parts of the buildings. These are specific and have time limitations.

NFPA 80 is a well-known and established standard for installation and maintenance of fire doors. Installer and third-party inspection bodies use this standard directly or create their processes inspired by its essence. Equivalent standards to this in Europe or other parts of the world are not very well known internationally (in case they are any).

With every new investigation into the workings of passive fire protection (often triggered by tragedies); there is evolution of greater control needed.

Some door and/ or hardware manufacturers are now starting to offer extended warranty and maintenance packages to take care of such needs.

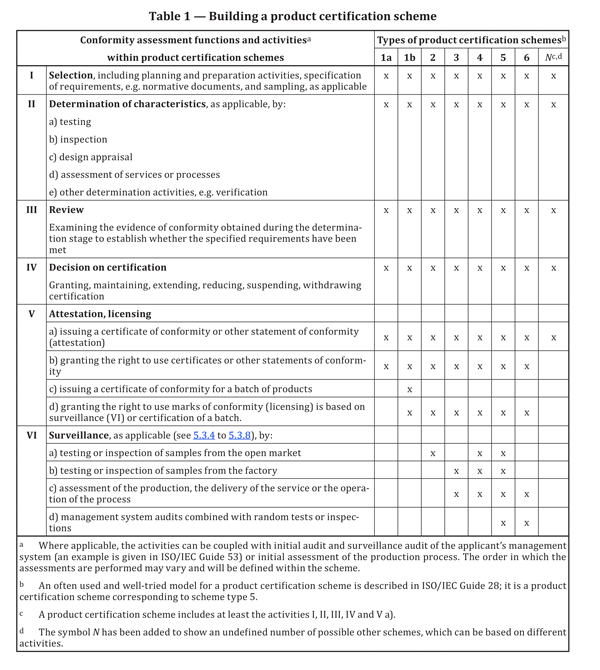

This is drawn from the standard which describes the fundamentals of product certification

and provides guidelines for understanding, developing, operating or maintaining certification schemes for products, processes and services and was published as part of the code. As an example of how this is used: The UAE Fire & Life Safety Code of Practice mandates a Type 5 conformity programme using Decree 213.

Conclusion

Since the ‘General Agreement on Tariffs and Trade’ moved to the ‘World Trade Organization’ (WTO) the trade across the world has been increasing rapidly over the decades. And so have the means of compliance evaluation. But the pandemic and the shifting geo-political relationships have been creating waves across supply chains which were earlier taken for granted. In such times, when we are dealing with ensuring Structural Fire Safety, it is critical that the correct use of means of compliance is understood and implemented.